2022-04-13by R-LIFTING

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to help you.

一、Types of Steel Wire Rope

1.Bright steel wire ropes without surface treatment, are made of quality high carbon steel and fully lubricated to protect the rope from corrosion.

2.Galvanized wire ropes with zinc coating for higher strength and excellent corrosion resistance are ideal for various general engineering applications.

3.Stainless steel wire ropes with better corrosion resistance are ideal for marine, decoration, architectural and other various applications.

4.Coated steel wire ropes are jacketed with PVC, polypropylene, nylon and other custom coatings in various colors for corrosion and wear resistance.

5.Elevator wire ropes with parallel laid structures, are available in six, eight and nine strands with FC or IWRC for different elevator applications.

6.Coated steel wire ropes are jacketed with PVC, polypropylene, nylon and other custom coatings in various colors for corrosion and wear resistance.

7.Rotation resistant wire ropes with outer strands twisted in the opposite direction to inner strands can minimize the tendency to spin and rotation.

8.Compacted wire ropes with crimped outer strands feature flattened surface, increase tensile strength and lateral compression strength, etc.

9.Mining wire ropes made of quality high carbon wires, are capable to withstand rugged working environments of surface and underground mining.

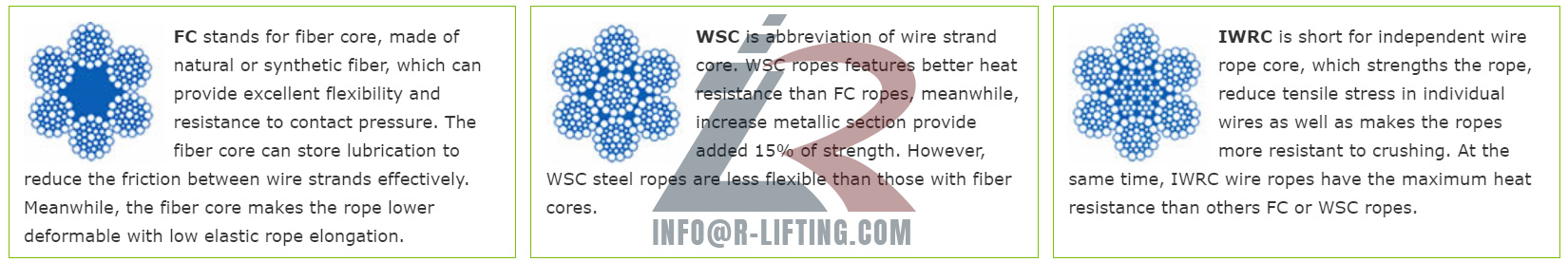

二、The Difference of Core FC, WSC or IWRC

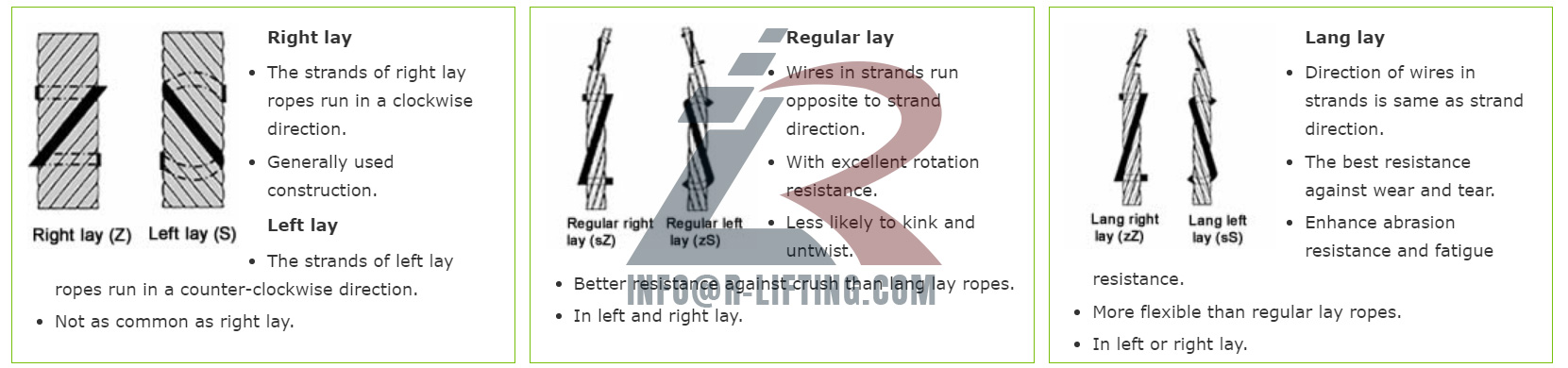

三、Regular, Lang or Alternative Lay?

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows: